The blister is a kind of fully transparent plastic. According to the plastic absorption process, the transparent plastic sheet is made into a special protrusion shape, which is covered on the surface of the product, which can be used for maintenance and decoration of the product. Also known as blister packaging machine. Vacuum pump cover.

How can a paper jam blister be produced?

Paper card sealed blister packaging test product.

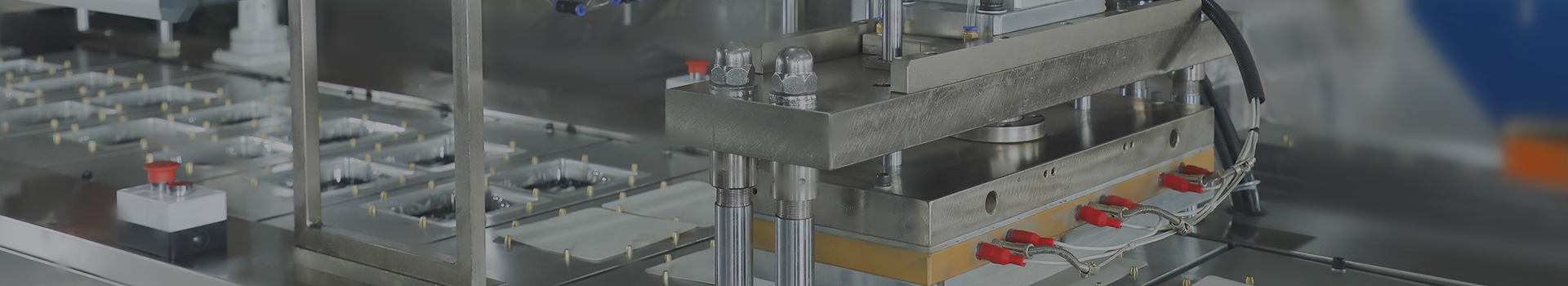

Four-station rotating automatic blister packaging machine.

The four-stop model show.

The basic principle of selecting high frequency heat melting:

Heat the product workpiece according to the high-frequency mold to melt the plastic and plastic. Plastic and paper card or paper card and paper card plastic connection. Melting paper cards are usually coated with polyethylene or APET in the packaging and printing process. PETG glue melts under the effect of high frequency machine.

characteristic:

1. This turntable machine has four stations, use time to set the conversion cycle time. An actual operator is on the machine to operate, and its production capacity can be achieved by a traditional two-station turntable. Two stations push automatic pipe cutting machine. Four times the three-station manual turntable machine. Because of the precise positioning of the indexer and the deep processing of the left and right templates, the quality of its electric welding has improved reliability in traditional handicrafts.

2. Use the shock system software as the source of electrostatic field to improve the reliability of the general shock system software on the sales market and reduce the probability of fire.

3. In order to better reduce the possibility of fire accidents due to actual operation problems, we use fire protection equipment to maintain the molds.

4.3-6 stations can be customized, automatic control of materials, saving human capital, improving production capacity, and improving yield.

Work content:

1. Feeding 1: The operator puts the blister into the mold; the turntable rotates for one station (90 degrees);

2. Feeding 2: The operator puts the paper card on the blister; the turntable rotates for one station (90 degrees);

3. High-frequency machine welding: lowering the top of the head-prestressing tension-welding-increasing pressure-refrigerating pressure test-raising the top of the head-turning the turntable for one station (90 degrees);

4. Material preparation station: mechanical arm fully automatic powerful suction cup, remove the packaged finished products; turntable rotate one station (90 degrees), enter the material 1

Part of the show:

Nowadays, the packaging method composed of paper card and plastic foam plastic casing can be said to be a hot spot in plastic packaging, which is particularly suitable for the development trend of size companies. Automatic loading, unloading and handling of machinery and equipment, saving manpower for actual operation and maintenance; PLC touch screens cooperate with system control, automatic common fault alarm reminders, common fault codes, and convenient maintenance

Post time: Dec-20-2021