According to a new report , three-quarters of battery blister packaging device respondents said their companies hope to make capital investments in the next 12-24 months, either by refurbishing old tools or buying new equipment.These decisions will be driven by technology, automation and regulations, as well as cost and return on investment.Regulations and disruptions caused by COVID-19 have also driven the demand for innovative and advanced equipment.

Automation: More than 60% of battery blister packaging processing and related service companies said that if they have the opportunity, they will choose to automate operations, and remote access becomes more necessary.

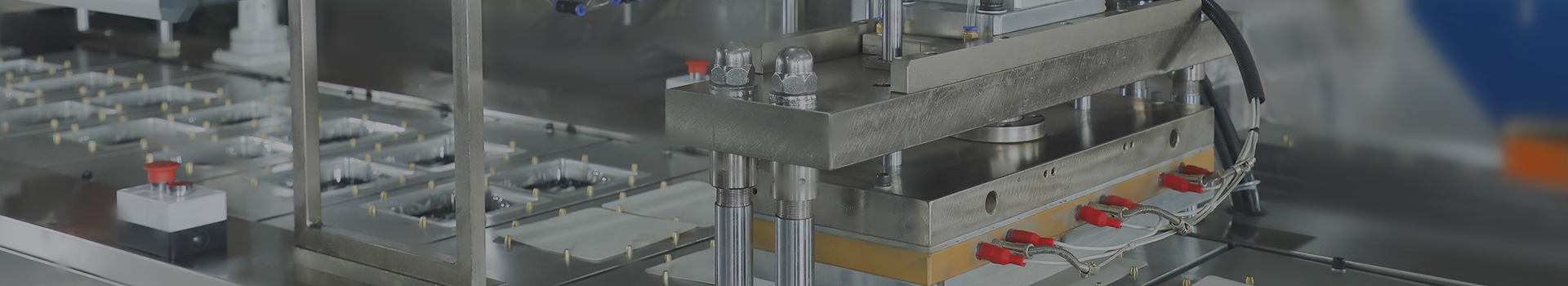

The company is investing in advanced machinery to increase packaging speed and efficiency.Examples of automated production line equipment include:

· The labeling system attaches wrap-around film or paper labels to containers at a speed of up to 600+ per minute.

· Form-Fill-Seal Technology, which uses a single piece of equipment to form plastic containers, fill the containers and provide air-tight seals for the containers.

· Due to the tamper-proof value and the separate tight seal, automatic blister packaging machines are becoming more and more popular.Automatic blister packaging improves the efficiency of the production line while maintaining consistency and quality.

· Digital technology, Internet of Things, and blockchain are helping companies connect their machines to smart devices, troubleshoot and report errors, optimize operations, gain insights into data between machines, and document the entire supply chain.

Self-administration has become more common, so the production of self-injection devices and pre-filled syringes has increased.The company is investing in assembly and filling equipment to achieve fast changeover times for various autoinjectors.

Personalized medicines are driving demand for machines that can package small batches with shorter lead times.These batches usually require agile and fast-paced scheduling by the pharmaceutical manufacturer.

Digital packaging that directly communicates with consumers to ensure medical monitoring and improve patient treatment results.

With the continuous increase of product types, packaging companies increasingly require flexible production in which machines can be changed from one product size to another.Respondents pointed out that as the pharmaceutical industry moves toward more personalized medicines, more and more batches have more unique sizes, sizes, and formulas, and portable or small-batch machines will become a trend.

Sustainability is the focus of many companies because they want to reduce waste and increase cost efficiency.Packaging has become more environmentally friendly, with more emphasis on materials and recyclability.

To view battery blister packaging automation, packaging and materials solutions, please view more information in our website.

Post time: Dec-22-2021