Razor Packaging Machine: Simplifying the Packaging Process

In today’s fast-paced world, convenience is king and the packaging industry plays a vital role in ensuring that products are not only protected but also presented in an attractive manner. The razor packaging machine is one such machine that revolutionizes razor packaging. With its advanced technology and automated processes, it has become a staple in the manufacturing industry, streamlining the packaging process like never before.

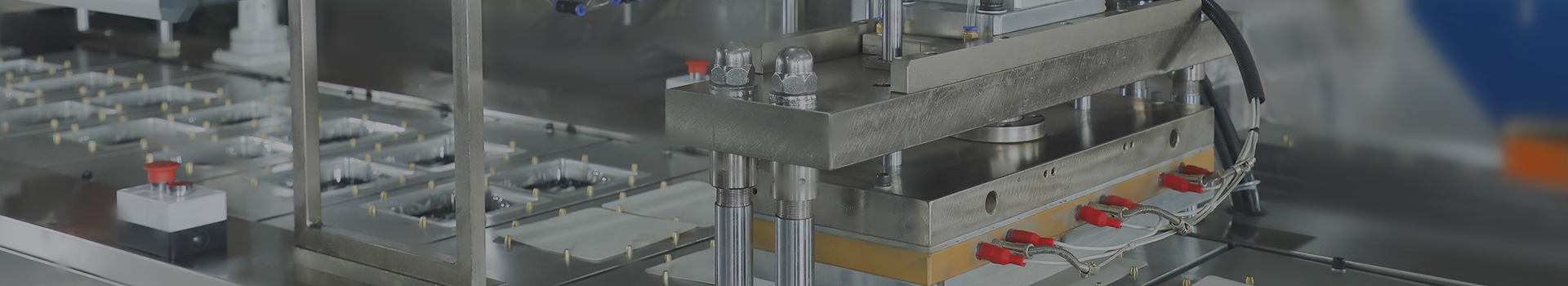

Razor packaging machines are engineered to meet the specific requirements of razor packaging efficiently and effectively. The machines are equipped with state-of-the-art features including automatic feeding systems, precision cutting mechanisms and high-speed packaging capabilities. The use of this advanced technology eliminates the need for manual intervention, reduces labor costs, and minimizes the chance of errors or inconsistencies in packaging.

One of the main advantages of using a razor packaging machine is its ability to handle a variety of razor types, including disposable razors, safety razors, and electric razors. These machines are designed to handle different sizes, shapes and packaging materials, ensuring that each shaver is packaged with precision and care. The automatic feeding system accommodates various types of shavers, allowing for seamless integration into production lines.

Speed is another key differentiator for the Razor packaging machines. These machines enable high-speed packaging, ensuring that large quantities of razors can be packaged quickly and efficiently. The machine is capable of packaging up to hundreds of razors per minute, significantly increasing productivity and meeting the demanding requirements of large-scale production facilities. By maximizing production, manufacturers can meet growing market demand and stay ahead of the competition.

Additionally, the Razor packaging machine is designed to optimize material usage and reduce overall packaging costs. The machines are programmed to use the optimal amount of packaging material required for each razor, minimizing waste and maximizing cost efficiency. Not only does this result in significant cost savings for manufacturers, it also promotes environmental sustainability by reducing the consumption of packaging materials.

Another significant advantage of using a razor packaging machine is guaranteed product integrity. These machines are designed to ensure that each razor is precisely cut and accurately positioned within the package, resulting in a clean and professional appearance. This attention to detail enhances brand image and consumer trust, as end users are more likely to perceive a beautifully packaged product as being of high quality.

Maintenance and user-friendliness are also important factors to consider when investing in a razor packaging machine. These machines can withstand heavy use and are relatively easy to maintain. Regular service and preventive maintenance ensures these machines are running at peak performance, minimizing downtime and maximizing productivity.

To sum up, the razor packaging machine has undoubtedly changed the packaging process of razors. With its advanced technology, high-speed capabilities and precision packaging, it has become an indispensable tool for manufacturers. By eliminating manual intervention, optimizing material usage and ensuring product integrity, Razor packaging machines streamline the packaging process, making it more efficient, cost-effective and environmentally sustainable. As the demand for razors continues to grow, investing in a razor packaging machine is a wise choice for manufacturers who want to stay ahead in the competitive market.

Post time: Oct-21-2023