A good toothbrush packaging machine/toothbrush packaging machine is an indispensable industrial equipment in the process of everyone’s use. We need to repair and maintain it. Let’s talk about everyone’s automatic packaging machine maintenance. Care and Maintenance:

1. The toothbrush packaging machine should be used in the conditions where the temperature is -10℃-50℃, the relative air humidity does not exceed 85%, and the surrounding atmosphere is resistant to corrosive gas, dust, and no flammability risk.

Like the automatic packing machine and refrigeration unit, this toothbrush packing machine is a three-phase 380V switching power supply circuit.

2. To ensure the normal operation of the toothbrush pump for the toothbrush packaging machine, the toothbrush pump motor cannot be allowed to rotate. The automatic packaging machine for oil tea three-dimensional protective film should be checked frequently. Usually, the remaining oil is 1/2-3/4 of the oil window (no more than that). It should be replaced with new oil (generally, it should be replaced once every one or two months, and it is ok to use 1# toothbrush gasoline or 30# vehicle gasoline and lubricating oil).

3. The sediment filter system should be disassembled and assembled frequently (generally cleaned once every 1-2 months, if the packaging fragments are crystallized, the cleaning time should be reduced).

4. After 2-3 months of continuous operation, the cover plate 30 should be opened to add lubricating grease to the reversing part and the bump of the main switch of the power supply, and lubricating the continuous behavior of the electric heating rod according to the application situation.

5. Frequent inspections should be carried out on the triple parts 24 of pressure release, filtration and organic waste gas to ensure that there is automobile oil (lubricating butter) in the organic waste gas and oil mark, and there is no water in the filter cup.

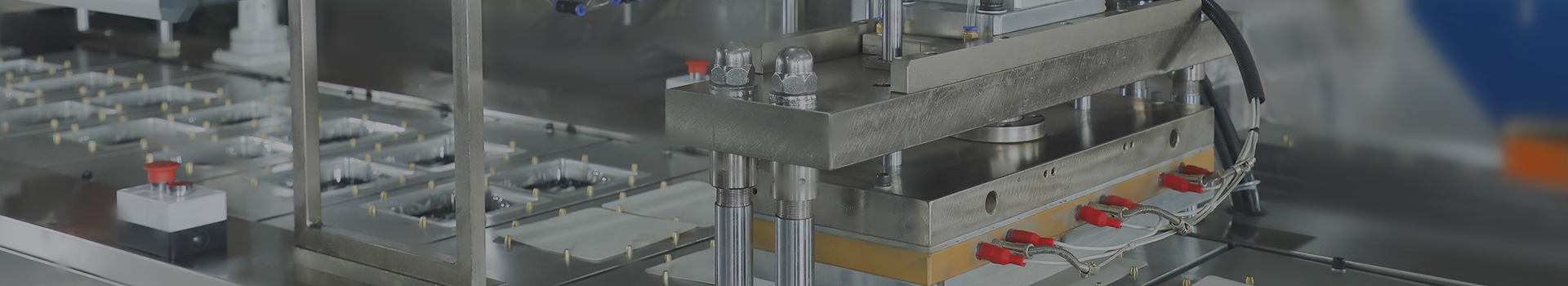

Click to add picture description (up to 60 words)

6. The heating strip and the silicone sealing strip should be connected to each other for cleaning, and they should not be stained with unclean things to prevent damage to the sealing quality.

7. On the electric heating rod, the second layer of paste under the heating plate is harmful to the cable sheath. When it is damaged, it should be replaced immediately to prevent short-circuit failure.

8. The customer reserves the working pneumatic control valve and the refueling pneumatic control valve. The working pressure of the toothbrush packaging machine has been set to 0.3MPa, which is suitable for comparison.

9. The toothbrush packaging machine cannot be allowed to be placed skewed and impacted during the entire transportation process, let alone tipped for transportation.

10. The toothbrush packaging machine must have reliable grounding protection during storage.

11. It is strictly forbidden to put your hands under the electric heating rod to avoid injury. In case of critical situations, the switching power supply circuit is immediately disconnected.

12. When working, firstly ventilate naturally and then turn on the electricity. When closing the equipment, firstly close the program and then the air is completely exhausted.

Post time: Apr-26-2022