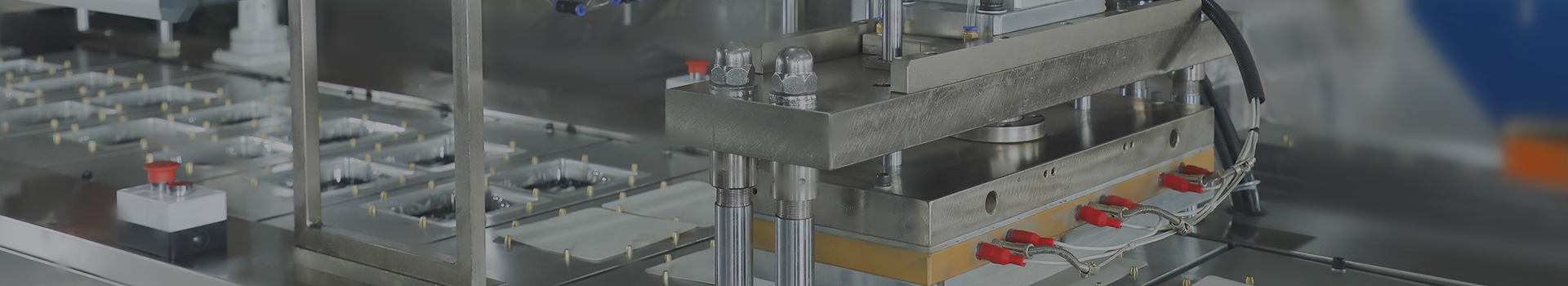

Blister packaging sealing machine: ensuring packaging safety and efficiency

Blister packaging sealing is a critical step in the packaging process in various industries. It involves sealing the products inside clear plastic blisters, ensuring they are protected from external factors such as moisture, dust and tampering. To accomplish this task effectively, blister pack sealants play a vital role. In this article, we’ll explore the importance of blister pack sealants and how they can help ensure the safety and efficiency of your packaging.

Blister packaging sealing machines are machines specially designed to automate the sealing process. They are equipped with advanced features and technology that make tasks not only easier, but also faster and more accurate. These sealing machines typically consist of a heating element, a conveyor system, and a control panel. The heating element melts the plastic material, while the conveyor system moves the blister packs through the sealing machine. The control panel enables the operator to set various parameters such as temperature, sealing time and pressure according to the specific requirements of the packaged product.

One of the main advantages of using blister pack sealants is the enhanced security they provide. By sealing products within blister packs, you protect them from external contaminants, reducing the risk of damage during transportation or storage. This is especially important for sensitive products such as pharmaceuticals, where maintaining the integrity of the packaging is critical to maintaining their efficacy. The blister pack sealing machine ensures that the product is securely sealed, preventing any possibility of tampering or unauthorized access.

Additionally, blister pack sealing machines help improve the overall efficiency of the packaging process. Manual sealing can be time-consuming and error-prone. Blister pack sealing machines, on the other hand, automate the process and significantly reduce the time required to seal each product. With their conveyor system, they can process large quantities of blister packs in a short time, making them suitable for high-volume production lines. Increased efficiency leads to higher productivity and ultimately increases business profitability.

Additionally, blister pack sealing machines are versatile and can accommodate a variety of products in different shapes and sizes. They can be easily adjusted to seal different sized blister packs, ensuring a precise fit for each product. This versatility enables businesses to use a single sealing machine to package a variety of items, whether pharmaceuticals, electronics or consumer goods. This eliminates the need for multiple machines and reduces the overall investment cost of the packaging operation.

In summary, blister pack sealing machines play a key role in ensuring safety and efficiency in the packaging industry. By automating the sealing process, they enhance the security of products, protecting them from external contaminants and tampering. Additionally, blister pack sealing machines increase the overall efficiency of packaging operations, reduce manual labor and increase productivity. Their versatility can easily package a variety of products, adding more value to the business. As the packaging industry continues to evolve, blister pack sealing machines are proving to be indispensable tools for achieving optimal packaging solutions.

Post time: Oct-28-2023