Blister forming machine, revolutionizing packaging solutions

Packaging is an important part of any industry as it ensures the protection and integrity of the product. Among various packaging technologies, blister packaging is popular for its ability to safely enclose products and prevent contamination, tampering and damage. In order to meet the growing demand for blister packaging, blister forming machines have emerged as a revolutionary solution.

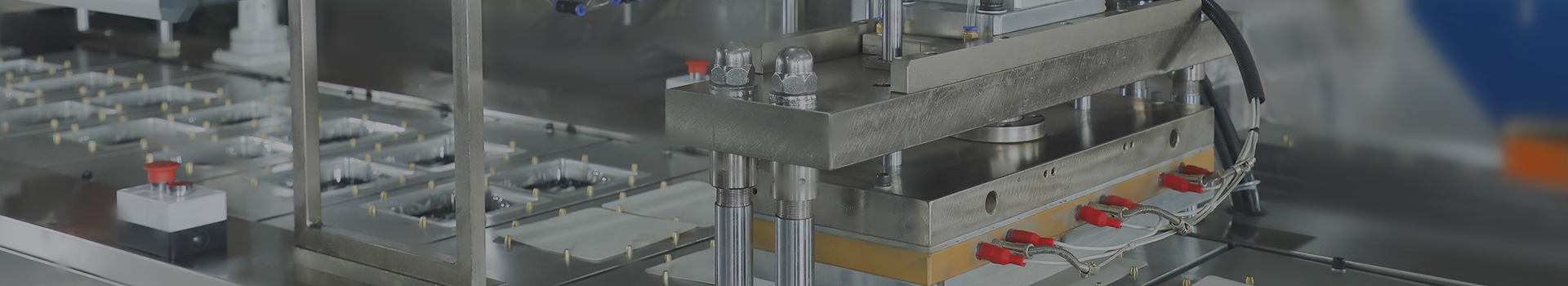

The blister forming machine is an advanced automated equipment specially designed for making blister packaging. These machines are equipped with state-of-the-art technology for efficient and accurate packaging. With their versatile designs and customization options, blister forming machines have become an important part of various industries such as pharmaceuticals, consumer goods, electronics and food packaging.

One of the main features of a blister forming machine is the ability to create custom blister packaging. Manufacturers can easily design and adjust blister pack size, shape and compartments to meet their specific product requirements. This flexibility provides better branding opportunities as companies can display their logos, product information and marketing messages on the blister packs. In addition, the clarity and transparency of blister packaging can better display products, attract consumers, and increase purchase opportunities.

The blister molding machine is easy to operate and efficient. It consists of heating system, forming device and sealing mechanism. A heating system softens the plastic material, which is then molded into the desired shape using vacuum or pressure forming techniques. Once the blister is formed, it is sealed with a backing material, creating a secure and tamper-proof enclosure for the product.

Efficiency is a key factor in the manufacturing process, and blister molding machines excel in this area. They can produce blister packs at high speeds, significantly increasing productivity. The automated nature of these machines minimizes the need for manual labor, thereby reducing costs and the risk of errors. Additionally, the blister molding process is reliable and consistent, ensuring the consistency of the final product.

In the pharmaceutical industry, blister packaging plays a vital role in maintaining the safety and effectiveness of medicines. Blister forming machines enable pharmaceutical companies to comply with strict quality standards and regulatory requirements. These machines can provide sterile packaging, ensuring that drugs remain free of contamination throughout their shelf life. The secure sealing of blister packs also prevents medication tampering, thereby protecting patient health.

Blister forming machines are not limited to the pharmaceutical industry. They also revolutionized packaging processes in various other areas. In the food industry, blister packaging ensures freshness and extends shelf life of perishable products. In the consumer goods industry, blister packaging provides attractive and practical packaging solutions for products of different shapes and sizes.

In short, blister forming machines have brought significant changes to the packaging industry. Their ability to produce custom blister packs, high production speeds, and adherence to quality standards make them indispensable in various industries. As the demand for efficient and safe packaging solutions continues to increase, blister molding machines are expected to become more advanced, offering enhanced features and functionality.

Post time: Sep-16-2023