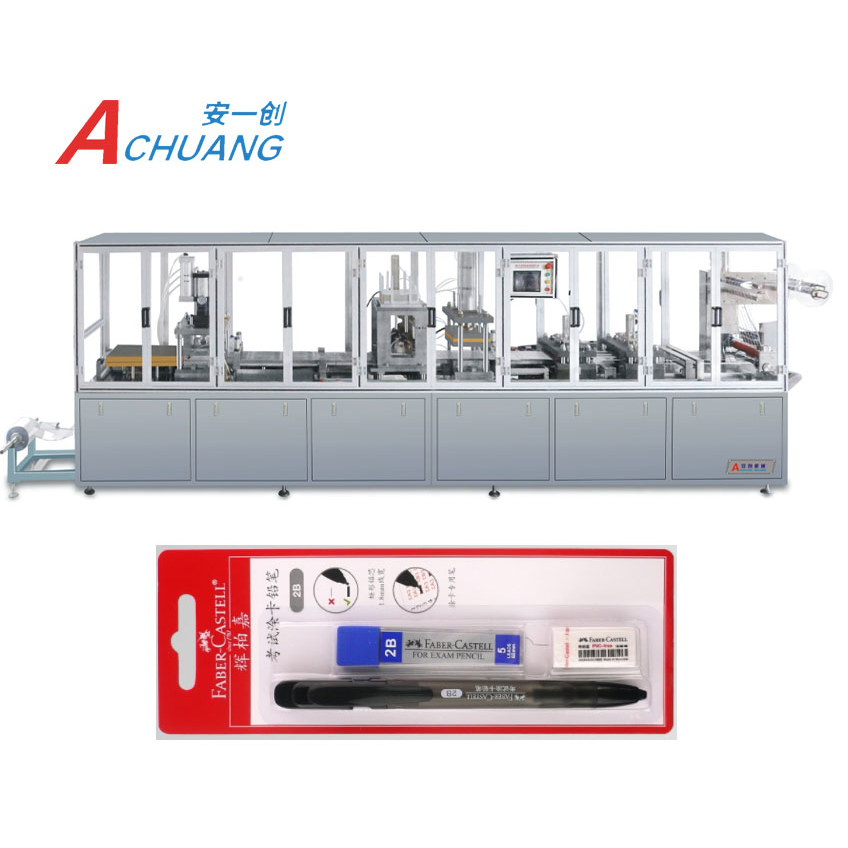

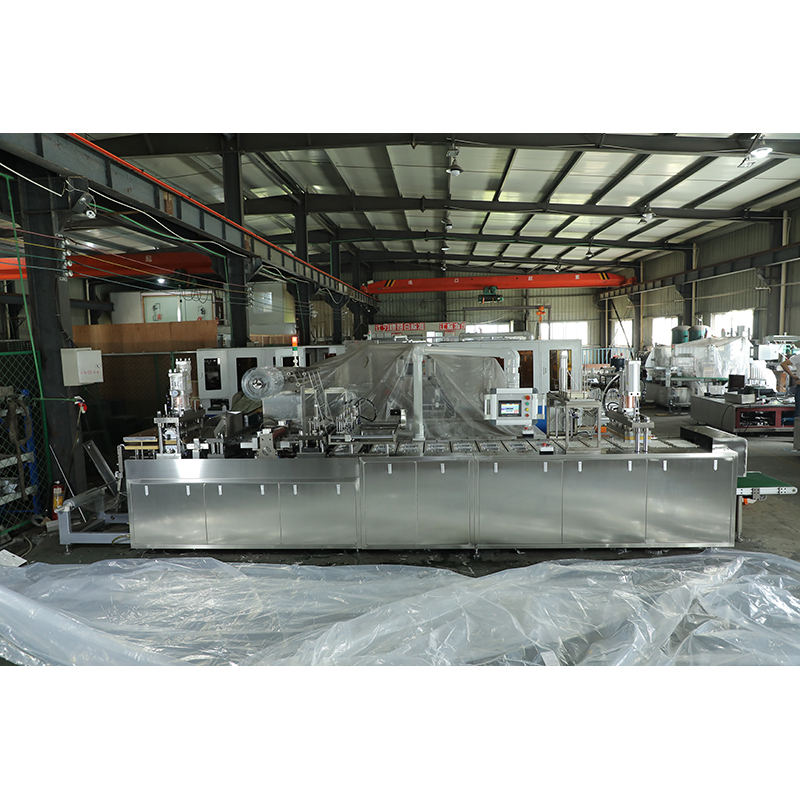

Top Suppliers High Frequency Blister Packing Machine - AC-600 Automatic Blister Paper Card Packing Machine – Anchuang

Top Suppliers High Frequency Blister Packing Machine - AC-600 Automatic Blister Paper Card Packing Machine – Anchuang Detail:

Usage

AC-600 is Suitable for half-cover sealed blister packaging, such as daily commodity, small hardware (battery, electronics, glue), stationery (pencil, eraser, correction fluid, solid glue), auto part (brake pads, spark plugs), cosmetics (lipsticks), toys (small cars) etc.

Appliance

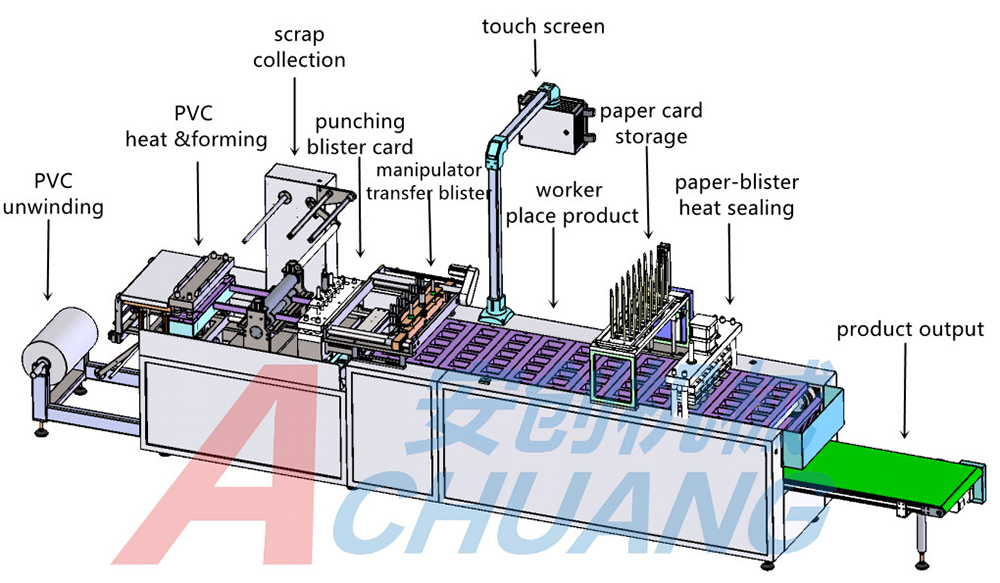

Function

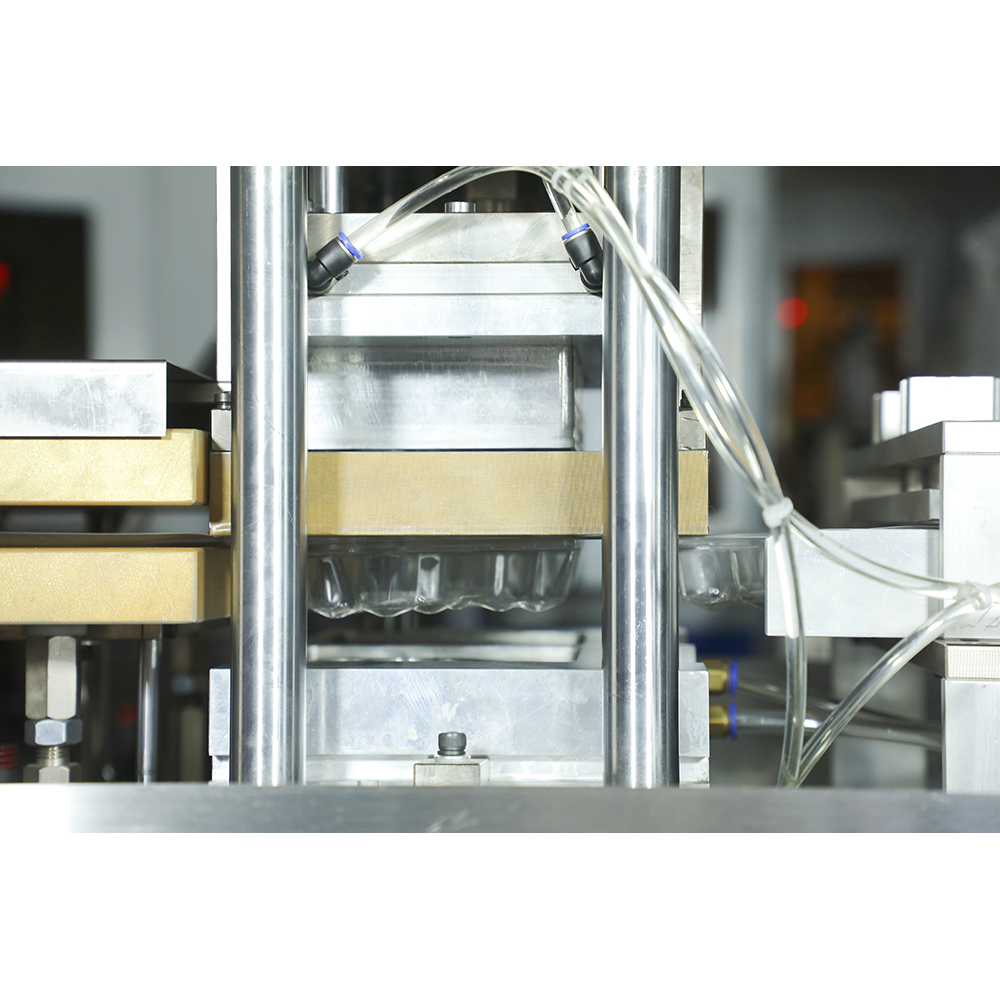

–Automatic forming blister, punching the blister, scrap collect,dropping paper card, paper blister heat sealing, product output automatically.

–Accurate temperature control module, PVC shortage alarm, insufficient air pressure auto stop, auto warning for damaged electrical parts.

–Human-machine interface and PLC control system, and is equipped with counting, starting password, fault reminder, maintenance reminder and other functions.

Main Technical Parameter

| Production speed | 15-18 times/ min |

| Max forming area | 500mm*180mm |

| Max forming depth | 35mm |

| Forming heating power | 3.5kw(*2) |

| Heating Sealing Power | 4.5kw |

| Total Power | 13kw |

| Air consumption | consumption ≥0.5m³/min |

| Air Pressure | 0.5-0.8mpa |

| Material thickness(PVC)(PET) | 0.15mm-0.5mm |

| Max paper dimension | 600mm*200mm*0.5mm |

| Weight | 2500kg |

| Dimension(L*W*H) | 5000mm *1100mm*1800mm |

Flow Diagram

PVC heating→blister forming→servo traction→blister cutting→PVC scrap collection→blister transfer to the chain plate→worker place product→paper card lay down →hot sealing→product output

(optional choice:labelling machine, ink-jet printer)

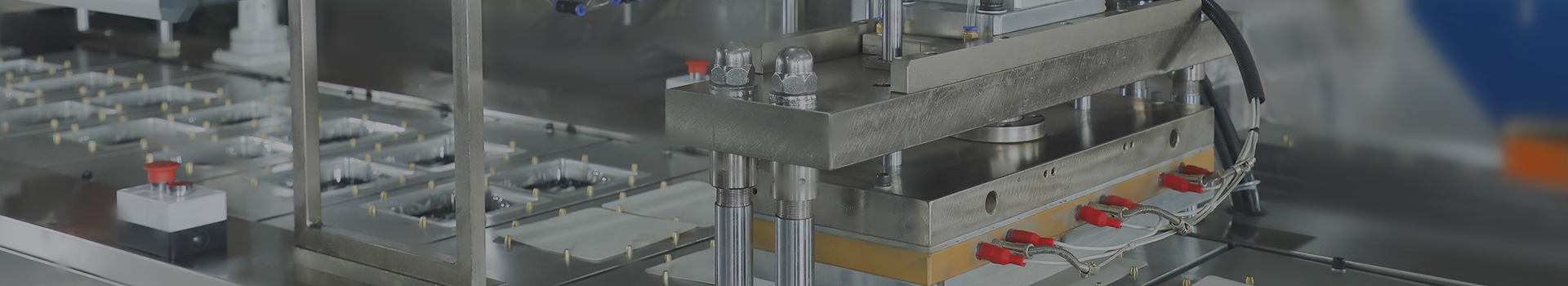

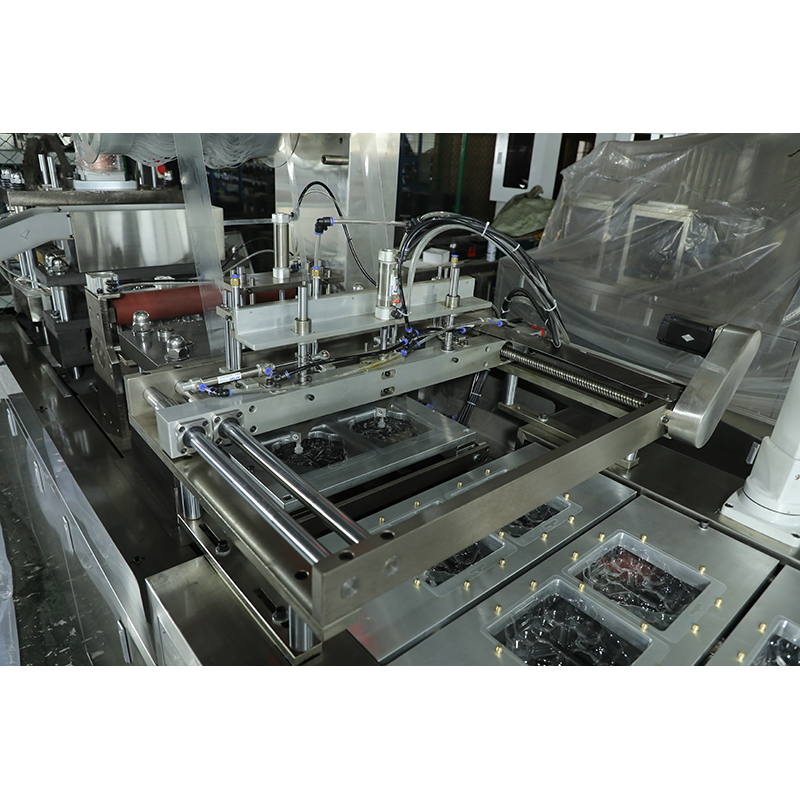

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Top Suppliers High Frequency Blister Packing Machine - AC-600 Automatic Blister Paper Card Packing Machine – Anchuang , The product will supply to all over the world, such as: Uruguay, Greek, Suriname, Our products are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, please contact us today. We will sincerely create and share success with all clients.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!