Top Suppliers High Frequency Blister Packing Machine - AC-350 Automatic Blister Paper Card Packing Machine – Anchuang

Top Suppliers High Frequency Blister Packing Machine - AC-350 Automatic Blister Paper Card Packing Machine – Anchuang Detail:

Function

–Automatic forming blister,cutting, dropping paper card, heat sealing, automatic product output and scrap collection.

–Accurate temperature control module, PVC fragments and insufficient air pressure auto stop and automatic fault source for damaged electrical parts.

–Human-machine interface and PLC control system, and is equipped with counting, starting password, fault reminder, maintenance reminder and other functions.

Appliance

Main parameter

| Production speed | 15-18 mold/min |

| Stroke range | 30mm-200mm |

| Max forming area | 320mm*160mm |

| Max standard forming depth | 35mm |

| Max non-standard forming depth | 50mm |

| Forming heating power | 3.5kw(*2) |

| Heat sealing power | 2.5kw |

| Total power | 12kw |

| Air consumption(air compressor) | consumption ≥0.5 m³/min |

| Air Pressure | 0.5-0.8mpa |

| Mold cooling water (chiller) | 50 L/h |

| Packing material(PVC)(PET) | thickness0.15mm-0.5mm内 |

| Packing material (cardboard) | 200g-500g |

| Space between forming blister | 5mm |

| Space between paper card | 10mm |

| Max paper dimension | 400mm*200mm*0.5mm |

| Total Weight | 2100kg |

| Machine dimension(L*W*H) | 3300mm*1700mm*1850mm |

Flow Diagram

Working procedure:

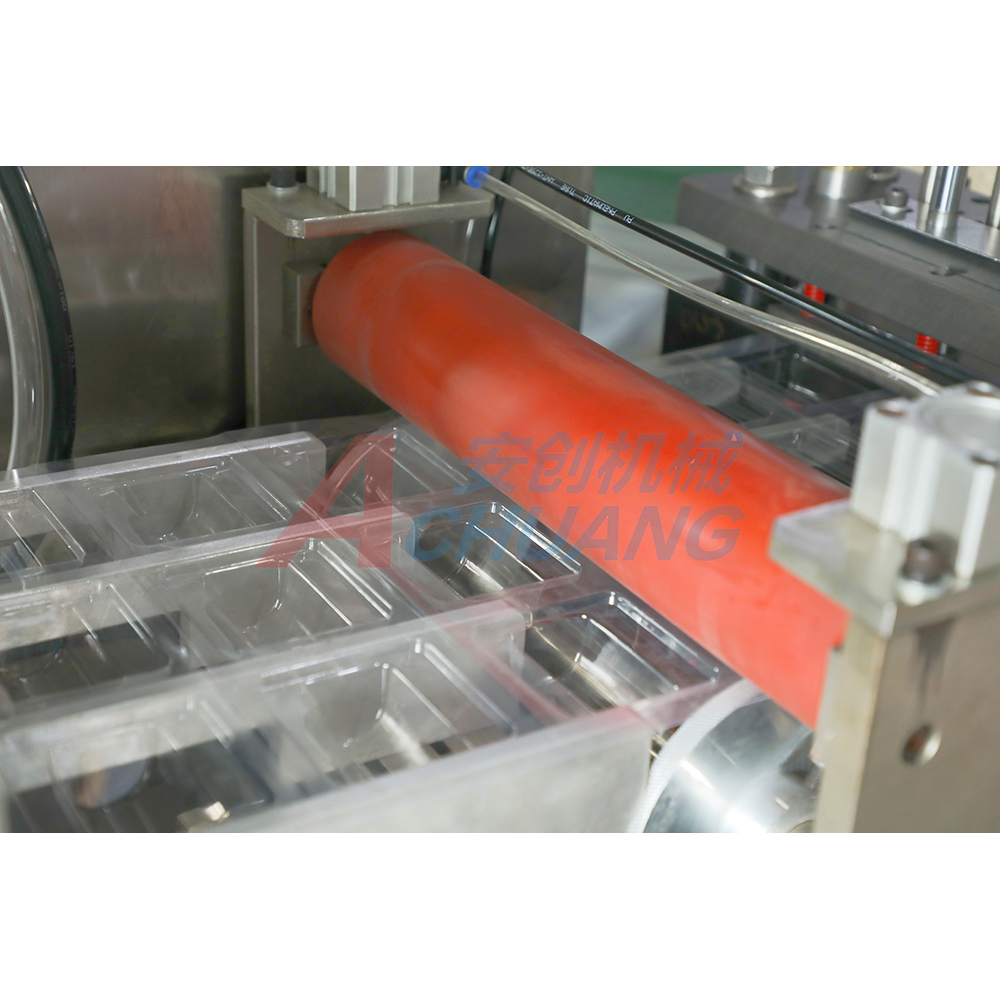

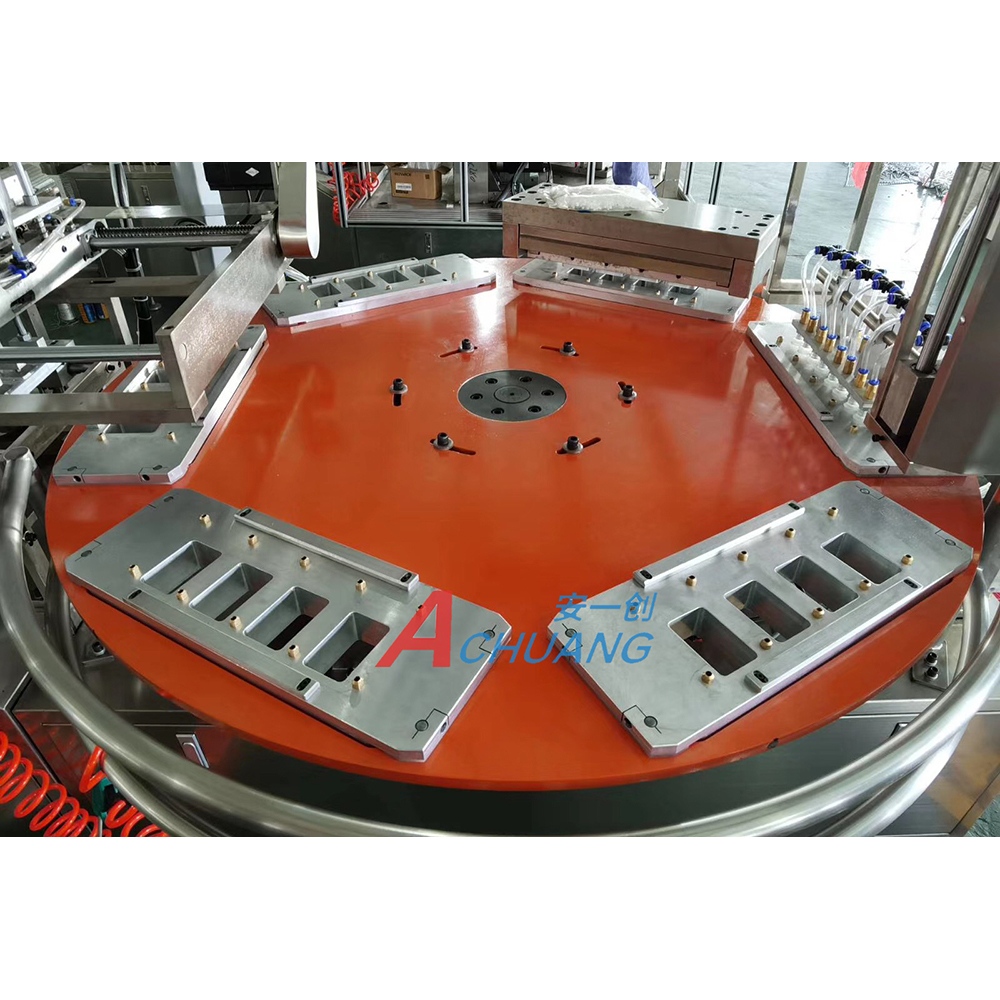

PVC loading→PVC heating→bliser forming→servo traction→blister cutting→PVC scrap collection→blister transfer→Manual operation→paper card lay down →hot sealing→product output

(optional choice:labelling machine, ink-jet printer)

Three-view Drawing

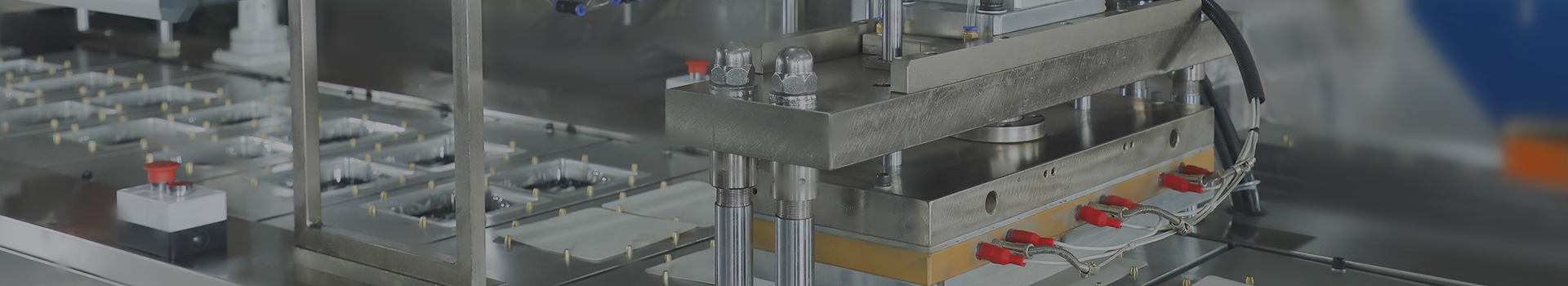

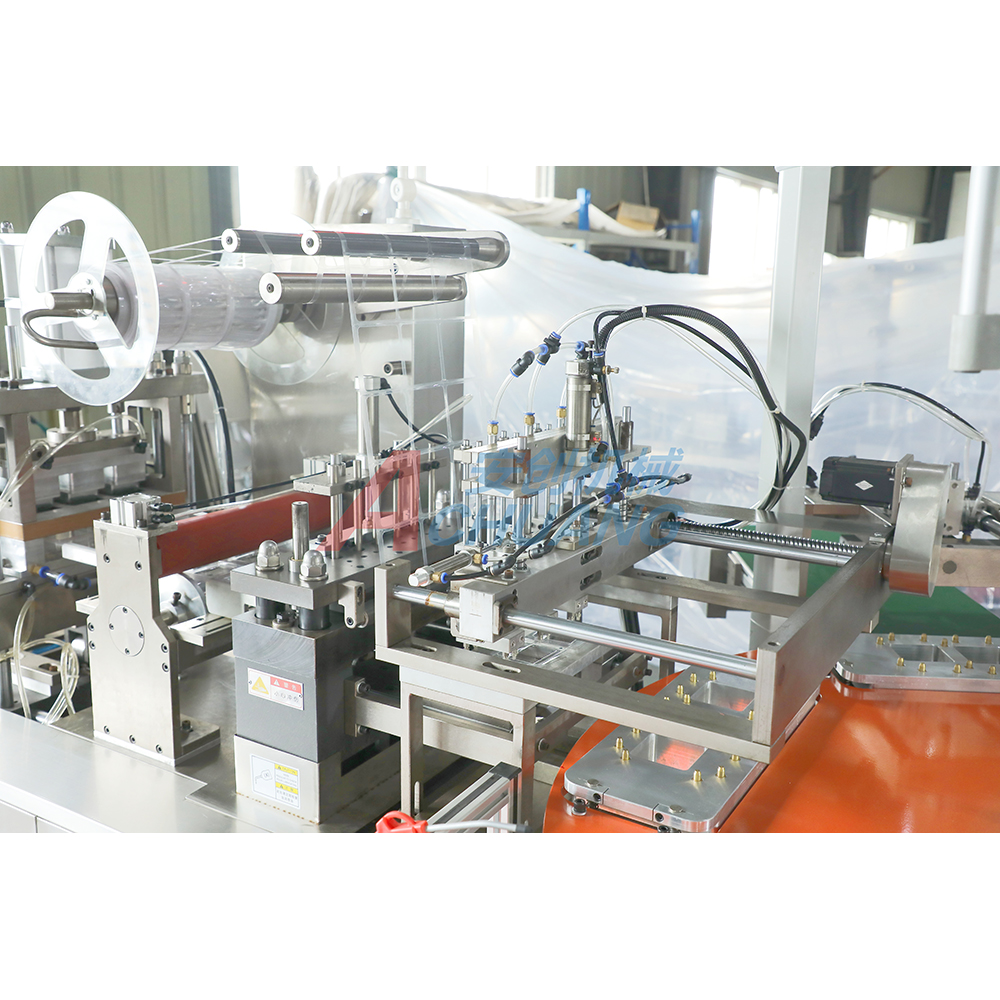

Product detail pictures:

Related Product Guide:

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of Top Suppliers High Frequency Blister Packing Machine - AC-350 Automatic Blister Paper Card Packing Machine – Anchuang , The product will supply to all over the world, such as: Kuala Lumpur, Cyprus, Algeria, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Write your message here and send it to us