Blister packaging machine (also called thermoplastic molding machine) is a machine that absorbs thermoplastic materials such as PVC and PE that are heated and plasticized into advanced packaging boxes, frames and other products of various shapes. Blister molding, also known as thermoplastic molding, mainly uses the vacuum suction generated by a vacuum pump to heat and soften PVC, PET, PETG, APTT, PP, PE, PS, etc. Divided into daily necessities blister packaging, hardware blister packaging, automotive supplies blister packaging, etc.

Common products on the market are: blister packaging for daily necessities, hardware, automotive supplies, electronic products, food, cosmetics, computer peripherals, toys, sporting goods, stationery, etc.

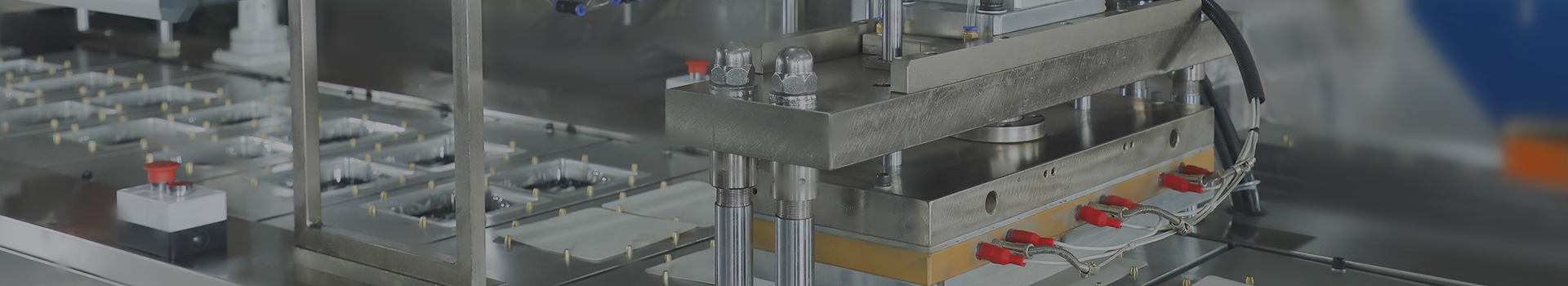

structure:

Its main structure consists of feeding, traction, upper and lower electric heating furnace, lower gate, multi-function adjustable size, lower template, upper mold, upper gate, knife switch, cutting and placing, and vacuum device. Pneumatic device is the main power source, and the pull tab and feeder are made up of electric, reducer, time relay, intermediate relay, travel switch and other electrical appliances to form a fully automatic control system.

The requirements for the control system of the blister machine are to ensure easy operation, high precision of mechanical action and temperature control, short production time, and to save the power consumption of the machine as much as possible under the same production conditions.

Post time: Sep-05-2022