Factory Cheap Razor Packing Machine - AC-350B series Battery Blister Packing machine – Anchuang

Factory Cheap Razor Packing Machine - AC-350B series Battery Blister Packing machine – Anchuang Detail:

Usage

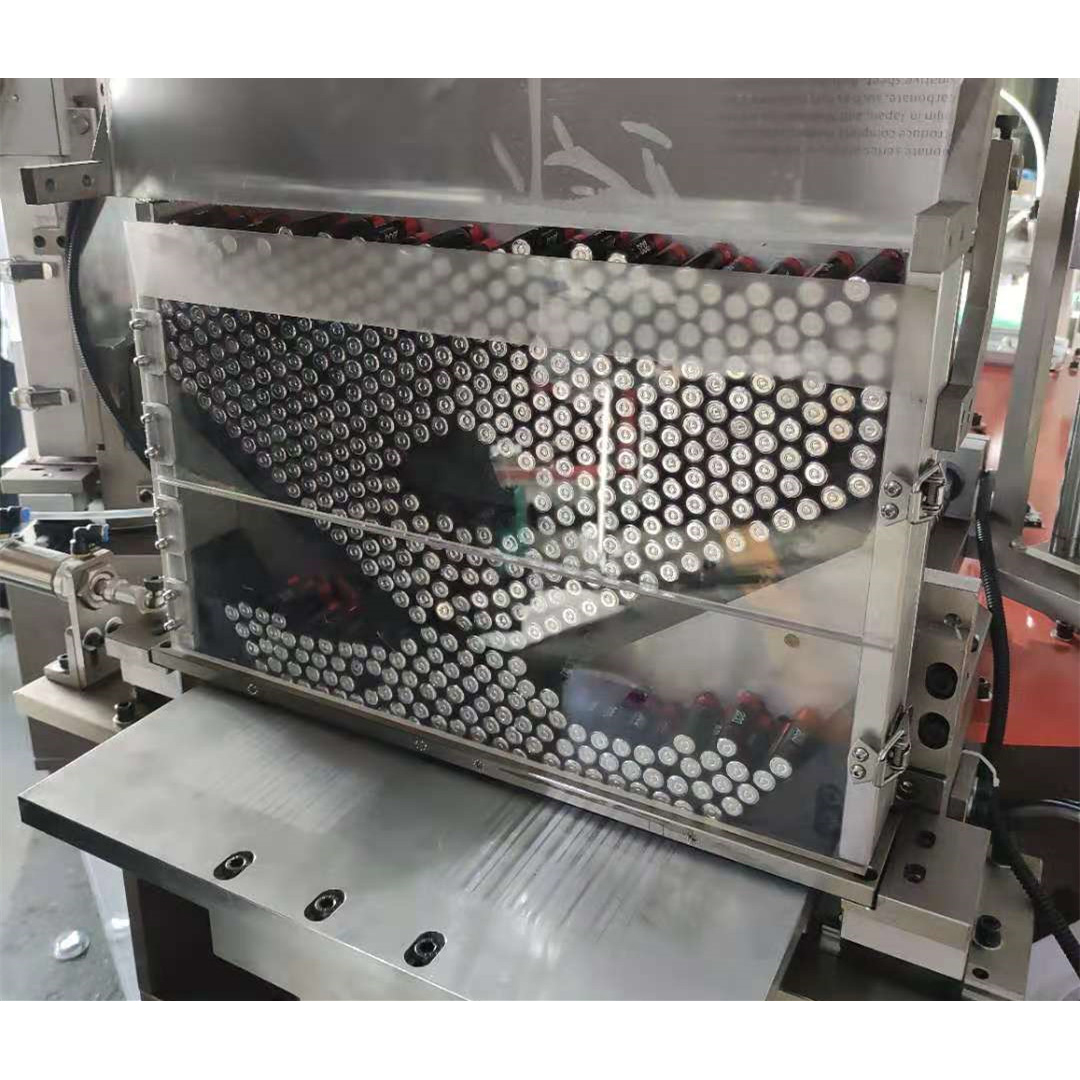

AC-350B series is widely used in the battery packaging industry. By designed and customized the battery feeder, we can realize different package for various battery types.

Function

–Automatic forming blister, punching the blister, scrap collect,dropping paper card, paper blister heat sealing, product output automatically. –Accurate temperature control module, PVC shortage alarm, insufficient air pressure auto stop and automatic warning for damaged electrical parts. –Human-machine interface and PLC control system, and is equipped with counting, starting password, fault reminder, maintenance reminder and other functions.

Main parameter

| Production speed | 15-18 times/min |

| Stroke range | 30mm-200mm |

| Max forming area | 320mm*160mm |

| Max standard forming depth | 35mm |

| Forming heating power | 3.5kw(*2) |

| Heat sealing power | 2.5kw |

| Total power | 12kw |

| Air consumption(air compressor) | consumption ≥0.5 m³/min |

| Air Pressure | 0.5-0.8mpa |

| Mold cooling water (chiller) | 50 L/h |

| Packing material(PVC)(PET) | thickness0.15mm-0.5mm内 |

| Packing material (cardboard) | 200g-500g |

| Max paper dimension | 400mm*200mm*0.5mm |

| Total Weight | 2100kg |

| Machine dimension(L*W*H) | 3300mm*1700mm*1850mm |

Flow Diagram

Working procedure: PVC loading→PVC heating→blister forming→servo traction→blister cutting→PVC scrap collection→blister transfer to the turntable→battery feeder working→paper card lay down →hot sealing→product output (optional choice:labelling machine, ink-jet printer)

Fig1. R0306 battery packing machine model

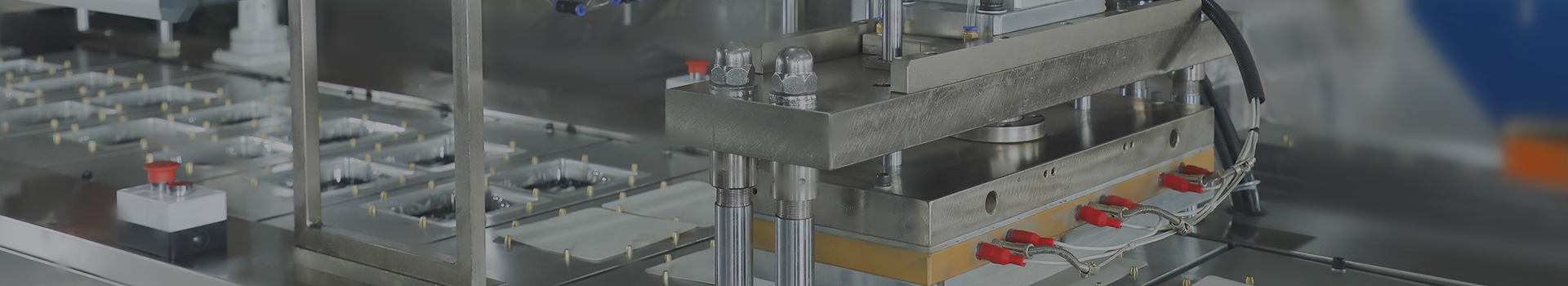

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for Factory Cheap Razor Packing Machine - AC-350B series Battery Blister Packing machine – Anchuang , The product will supply to all over the world, such as: Malawi, US, Angola, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.